Energy efficiency – the key to success in the future of manufacturing

By energy efficiency, some people mean to put off the lights while leaving a room, make less use of cars, or make use of energy-saving modes on devices. Energy efficiency means to do more with less energy instead of wasting it as useless heat. It is very crucial to generate to reduce greenhouse gases and fight the negative consequences of climate change as the world’s energy needs are growing constantly.

It is important for businesses to focus on improving their energy efficiency. Energy-efficient is the efficient use of energy by businesses or households. Energy efficiency is the goal to reduce energy consumption within all areas of a business-like in a production line or office. Energy efficiency improvements are when the water temperature of the boiler is reduced by one degree or the building premises is insulated so that it used less heating and cooling.

|

| Source: solarfeeds.com |

Energy efficiency is one of the major issues confronting businesses especially the manufacturing sector. A reduction in energy consumption reflects not only on the profits but also has a powerful impact on the company’s carbon footprint.

Various processes and pieces of equipment can be used to make an improvement in energy efficiency. The cost of specialized equipment to minimize wastage can be productive and cheaper and has less effective options especially when it comes to minimizing heat loss.

In a manufacturing unit, it is essential that specific temperatures are maintained. This helps to maintain perishable goods from getting spoiled or ensures that the manufacturing unit operates at optimum efficiency. The fluctuation in temperature results in increased energy bills as heating or cooling systems need to work outside of their most efficient parameters. To open and close doors in these areas is a troublesome factor in regard to maintaining a constant temperature since the displacement and movement of air from one room to another.

To maintain the temperature fluctuations one simple and cost-effective solution is to implement the installation of PVC strip curtains. The strip curtains help in maintaining constant temperature and also helps in maintaining a high level of pedestrian or motorized traffic. This acts as a barrier to airborne contaminants without any need for any energy source and minimal maintenance.

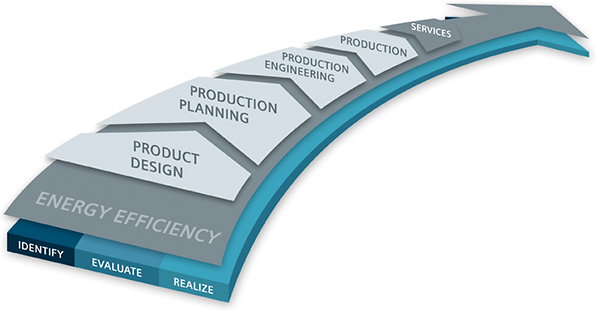

|

| Source: siemens.com |

Many of the industrial processes are likely to impact the environment and it is the duty of the companies to ensure that this impact is kept to a minimum. With the installation of PVC strips the manufacturing unit can reduce energy wastage and along with the small steps taken in the direction massive leaps can be made in lowering overhead costs and preserve the planet earth.

Manufacturing units can replace their old machinery with new and more efficient ones. Modern machinery will make use of less power. With this step in view, the manufacturing units can in the future replace energy-hungry equipment with more energy-efficient ones thus improving the overall business energy efficiency.

It is easy to achieve efficient energy use by making use of more energy-efficient technology or processes rather than by changing the individual behavior. In a manufacturing unit, one can design energy-efficient buildings in wake of the global call to save energy. To save the planet this will play a major part in reducing the global emission of greenhouse gases.

A small contribution by all in this direction will make big difference. It may be the replacement of incandescent bulbs with energy-saving bulbs or the installation of a green box to the heating/hot water system to lower the bills and reduce the electricity consumption. This ultimately will enable us to save money at the same time along with energy efficiency.

Register at SolutionBuggy to find manufacturing consultants/experts in quick time and get your projects done.

SolutionBuggy is an exclusive and dedicated platform for the Manufacturing Sector in India. It seamlessly bridges the gap between the industrial sector and professionals for on-demand consultation and services including projects. It connects SMEs and Large Scaled Industries with Industrial Consultants/ Experts and Industrial Product Suppliers over the internet for collaboration and success.

It is an integrated platform wherein industries can share their issues/ problems and post requirements; consultants/ experts can showcase their capabilities and offer services and solutions and suppliers can list their products to match the industry requirements.

Follow us at

280,084 total views, 508 views today

Talk to Our Expert

Solutions For

Reach Us

Bangalore (Head Office)

#249, 2nd floor, 14th Main Rd, Sector 7, H.S.R Layout, Bangalore - 560102.

Across India : Delhi | Pune | Mumbai | Chennai | Ahmedabad | Hyderabad | Kolkata, and 30+ major cities across India

Copyright © 2024 SolBuggy. All Rights Reserved

Consult NowCall UsWhatsApp(24/7)