Everything you need to know about process and product layout manufacturing

2017-03-18T10:29:00

By SolutionBuggy

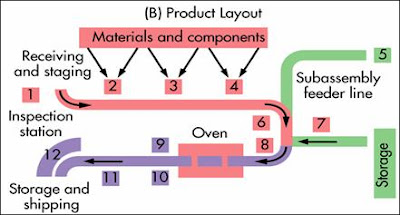

In manufacturing, a product layout refers to a production system where the workstations and equipment are located along the line of production as with assembly lines. The work units are usually moved along a line by a conveyor. Work is done in small amounts at each of the workstations on the line. The product layout can be used when the total work to be performed must be dividable into smaller tasks and is assigned to each of the workstations.

|

| Source: scrigroup.com |

Each of the workstations does small amounts of work, the stations utilize specific techniques and equipment as per the individual job they are assigned which leads to a higher rate of production.

Process layout is a design for the floor plan of a plant that aims to improve efficiency by arranging equipment according to the function. The design of the production line is done to eliminate waste in material flows, inventory handling, and management. According to a particular production sequence in the process layout, the workstations and machinery are not arranged. There is an assembly of similar operations or similar machinery in every department.

|

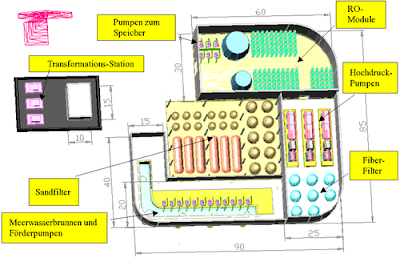

| Source: Wikipedia |

The manufacturing organizations put a lot of thought and do a lot of research regarding the layout of the facilities in the factory. It is very critical to select the strategies for the manufacturing process and designing for increasing productivity and reduction of cost. Various strategies are adopted by companies in reducing wastage and increasing the output in lesser time. On the basis of various scenarios, either process layout or product layout are implemented by companies.

Below mentioned is an insight into everything one should know about the process and product layout manufacturing process.

Product Layout – Different workstations are grouped together according to the products they work on. In a product layout, workstations can quickly transfer small batches of semi-finished goods directly to the next station on a production line. For smaller manufacturing businesses, product layouts can be ideal with a small volume than their large corporate competitors. It is wise to at least consider implementing a process layout with the growing output in the manufacturing business. For a garment manufacturer, the product layout is, for example, stations for sewing cloth, sewing on buttons, inspecting seams, wrapping finished garments, and boxing them up cleanly and neatly. All the process is located within close proximity to an individual clothing item. This enables individual garments to pass from one station to another quickly.

Process Layout – According to the activities being performed process layout group workstations work together irrespective of which products each workstation is working on. At a time, workstations produce higher volumes of output before sending semi-finished goods in bulk to the next area. This may be located as close as the other end of a building or other side of the globe. For example in the case of garment manufacturing, a process layout would group multiple sewing stations together for different clothing items in one area and then locate inspection, wrapping, and packaging stations for different items together in different areas.

Advantages– Process Layout enables increasing economies of scale. This enables individual processes to function more efficiently with various resources. Due to this, process layouts are ideal for businesses that produce large volumes of products every day. Additional cost advantages in human resources are provided by process layout as employees get easily specialize in the specific work process. They also learn from coworkers and supervisors by doing the same job repeatedly. The advantage of Product layout is that it keeps specific production jobs relatively contained. This is ideal in the case of building manufactured homes with low-volume goods that need good communication between the workers at different stations.

Disadvantages – When dealing with individual custom orders the process layouts can be less effective, as custom information should be sent with the production line along with the semi-finished materials. The Product layouts on a large scale require more space than process layouts. This is due to the fact that tools and equipment cannot be shared easily between workers doing the same task on different products. The lack of layoff in production areas helps in increasing the total expenses for equipment as each extra station needs to have a full set of equipment and tools to perform the work independently.

Register at SolutionBuggy to find manufacturing consultants/experts in quick time and get your projects done.

SolutionBuggy is an exclusive and dedicated platform for the Manufacturing Sector in India. It seamlessly bridges the gap between the industrial sector and professionals for on-demand consultation and services including projects. It connects SMEs and Large Scaled Industries with Industrial Consultants/Experts and Industrial Product Suppliers over the internet for collaboration and success.

It is an integrated platform wherein industries can share their issues/ problems and post requirements; consultants/experts can showcase their capabilities and offer services and solutions and suppliers can list their products to match the industry requirements.

Talk to Our Expert

Solutions For

Reach Us

Bangalore (Head Office)

#249, 2nd floor, 14th Main Rd, Sector 7, H.S.R Layout, Bangalore - 560102.

Across India : Delhi | Pune | Mumbai | Chennai | Ahmedabad | Hyderabad | Kolkata, and 30+ major cities across India

Copyright © 2024 SolBuggy. All Rights Reserved

Consult NowCall UsWhatsApp(24/7)