India’s Top Textile Consultants Under One Roof

Avail Textile Consultancy services from the best experts in the country

660+

Textile Experts

570+

Projects Completed

950+

MSMEs Mentored

Talk to Our Textile Consultant

Leaders In Textile Industry

Awards & Media

About Textile Consultants from SolutionBuggy

India is one of the largest textile producers in the world and has a presence across the entire value chain from fiber to apparel in the textile industry. The Indian textiles market is expected to be worth more than US$ 209 billion by 2029. Abundant availability of raw materials and manpower, huge domestic market, better infrastructure, etc. are some of the factors driving the market growth in the country...

Read MoreIndian Textile at a glance

- India is the second largest producer of cotton in the world

- World’s largest consumer of cotton

- Second-largest producer of polyester, silk and fibre

- Textile industry is the second-largest employment provider in India

- India is the fifth largest exporter of textile and apparel in the world

- Textile industry accounts for 12% of total exports of India

- Textile and apparel industry accounts for more than 4% of India’s total GDP.

Companies Availed Textile Consulting Services

Different Types of Textile Industry Consultants We Offer

Textile fabric consultants

Selection of fibres in fabric manufacturing is needless to say the very first and the most prominent step that distinguishes the business. The conversion from fibre to fabric completely depends on choosing the accurate textile fibres from the various ranges of fibre that is available. These textile fibres that are most crucial in textile manufacturing can impact the complete manufacturing process. Hence, it inherently becomes risky to be carried out without proper knowledge or consultation. Our textile fabric consultants help you in the selection of the right kind of fabric for your industry.

- Selection of fibres is very important in the fabric manufacturing process

- The conversion of fibre into fabric depends on selection of fibres

- It is not advisable to select the fabric without prior knowledge or consultation

- Our textile fabric consultants assist you in selecting the textile fabric

Different Sectors in Textile Industry

SolutionBuggy has carved a niche in the Indian textile industry as one of the top textile consulting firms in India with the help of its textile experts who come with an average experience of 18 years. Till date, SolutionBuggy completed more than 570 textile consulting projects across the complete textile value chain. SolutionBuggy provides access to the top textile consultants in India who can help you assist you in addressing your technical, engineering, and business challenges.

If you are a new entrepreneur planning to start a textile industry or an existing industry facing issues with your textile business, then get assistance from India’s best textile experts from SolutionBuggy. Our textile manufacturing consultants assist textile industries to drive excellence in their manufacturing process using technology to further increase productivity. The textile industry in India comprises of various sub sectors including:

Get Details

Woven Fabric

Technical Textiles

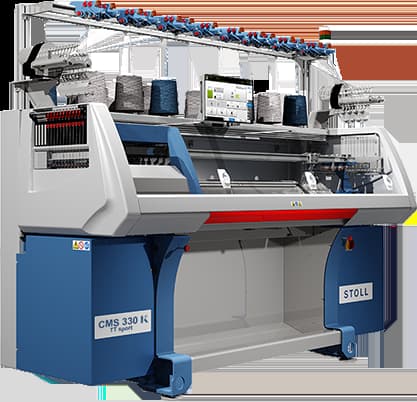

Knitted Fabrics & Articles

Yarn & Thread

Textile Finishing

Home Textiles

Business Opportunities in States

Andhra Pradesh

Andhra Pradesh is the second largest producer of cotton and raw silk in India. The state has a strong textile industry base consisting of handlooms, handicrafts, spinning and processing units. The state has integrated apparel city in Vizag with an innovative concept of ‘Fibre to Store’. The government is providing a lot of initiatives for the sector such as offering land for the establishment of textile and apparel parks, training programs, etc. The state has a good number of textile industries in the districts of Guntur, Chittoor, Kadapa and Kurnool.

Services

Market Research

Product Development

Plant Setup

Funding

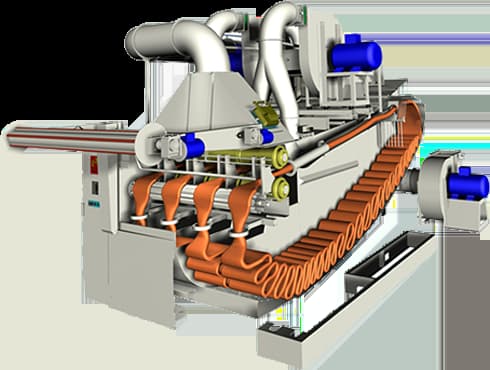

Machinery Installation

Technology Adoption

License & Certifications

Packaging & Distribution

Why Choose Us as Your Textile Consulting Services Partner?

There exist a lot of consulting firms in the market which serve Fortune 500 companies and other large scale enterprises. However, it is very difficult for MSMEs to find the relevant expert required to address their technical and business challenges. SolutionBuggy is particularly dedicated to small and medium scale industries in the country.

Our textile experts come with an average experience of 25 years working across several domains in the textile industry. Till date, SolutionBuggy completed more than 570+ textile consulting projects through its network of expert textile industry consultants. We provide you with the industry’s best textile consultants in India who can offer you the best textile consultancy services and help you address your business challenges and guide you towards success. If you are a new entrepreneur planning to start a textile manufacturing business or an existing industry facing challenges with your textile manufacturing business, then get help from the best textile industry consultants from SolutionBuggy.

Consultant ServicesWe offer you highly skilled, experienced, professional, and verified consultants for your business. They are trustworthy and offer insightful advice related to the textile manufacturing business. With our consultant’s advice, you can find the most effective solutions to your business needs.

Consultants registered with us are highly qualified. They offer you a variety of expertise, skills, and knowledge in the textile manufacturing sector. With our online platform, you can effortlessly discuss your needs and get valuable advice.

At Solution Buggy, we have a dedicated team fully responsible to help you find the right consultant. We aim to stand by you from the beginning of your journey until the end. We also ensure that your relationship with our consultants stays beneficial as well as mutual.

We ensure 100% confidentiality for both the manufacturers and consultants. You can post your requirements confidentially and we will not ask about any of your personal information.

To search for a consultant all by yourself requires a lot of your time, effort and money. However, at SolutionBuggy, we make it easier for you. In order to hire qualified consultants, you need to register SolutionBuggy and then post your requirements. Once you post your requirements, our consultants will reach out to you. With us, you are not wasting any time. You are simply putting your requirement and we hire the best one for you.

Popular Projects

Require consultant for product development of synthetic prin...

Location: Karnal, Haryana

Budget: 3 crores

Require consultant for textile disperse and vat printing on ...

Location: Ahmedabad

Budget: 1.5 crores

Require consultant for contract manufacturing of kids wear...

Location: Ranchi

Budget: 50 lakks

Solutions For

Reach Us

Bangalore (Head Office)

Across India : Delhi | Pune | Mumbai | Chennai | Ahmedabad | Hyderabad | Kolkata, and 30+ major cities across India

Copyright © 2024 SolBuggy. All Rights Reserved